Application note

Internet of things is a Coffee Machine

Designed by illycaffè, with Bluewind

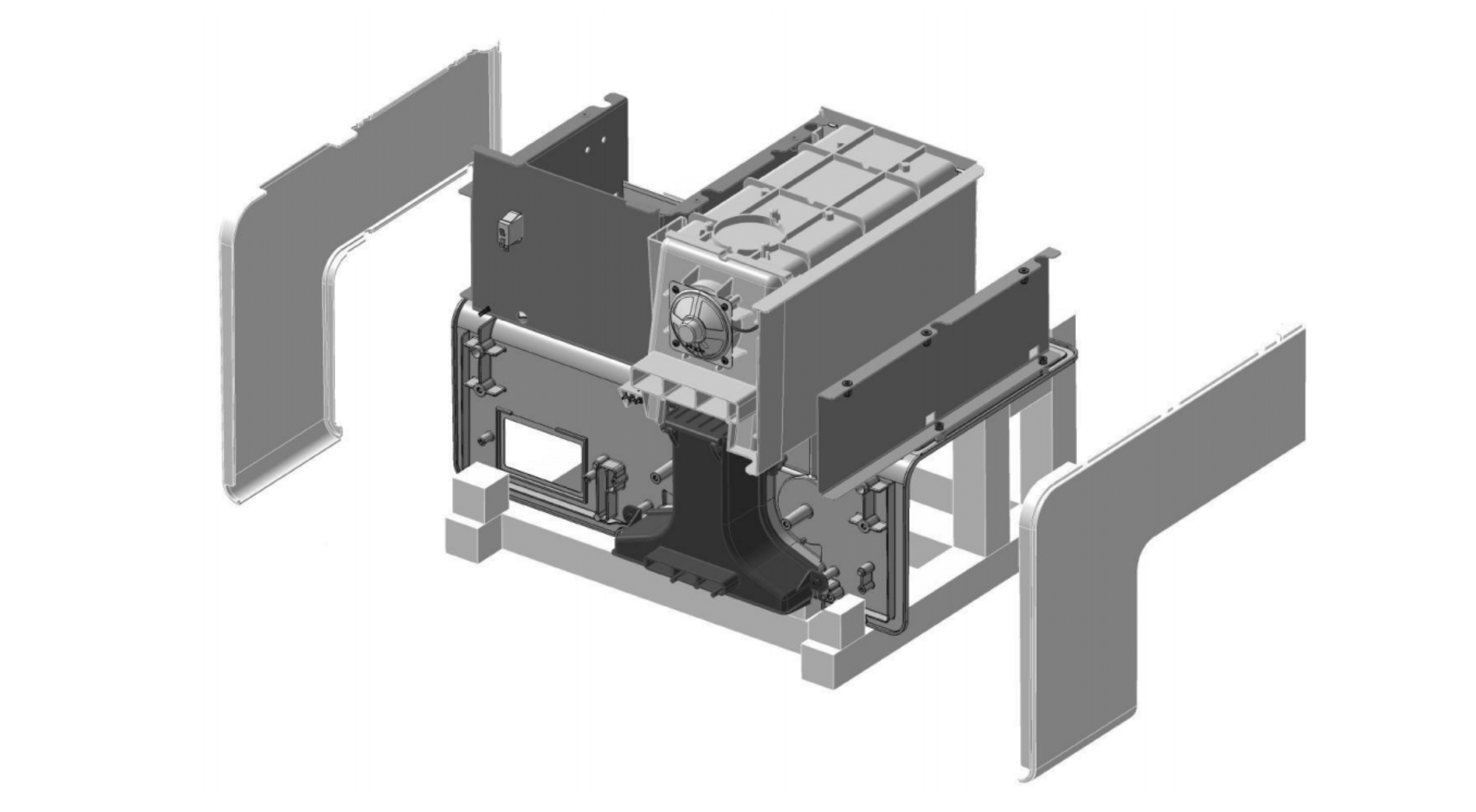

The Y2 HoReCa professional Coffee machine, is a good example of ioT in the vending field. Y2 sports all the latest communication technologies, in a brilliant and sleek design. Y2 is connected to the internet cloud, through GPRS or Wi-Fi connectivity, allowing for product marketing analysis and device maintenance. The Y2 is powered by rugged CPU running Linux Embedded, and includes a high level graphical display interface, similar to the one available on the latest Smartphones, based on QTembedded.

Overview

This Hi End Professional Coffee Machine is Cloud Connected and with WiFi ready. Machine with sleek aesthetic and functionality, due to adoption of QT embedded graphics and MQTT/mosquitto opensource IoT technology.

Solution

The original Idea is translated into a series of sketches, concepts and mock-ups which underline the functional and physical appearance of the Product, along with its usability value.

Electronics

Depending on the overall machine Size, Electronics can be based on single or multiple board layout, including Power Supply and electronic valve triac control, communication channels (Uarts, GSM, Wi-Fi), and graphical Interfaces display and User Interface.

Software

For simple machines, single CPU can suit the design. For more complex systems, also a Linux based solutions can be suitable for the complexity of: communication tasks, real time tasks, graphics UI, and up to TCP/IP requirements (WiFi)

Costs of Cloud Connectivity

Data connectivity is mandatory for last generation Vending Machines. This is obtained through the mix of two main technologies: GSM and Wi-Fi. In IoT based vending devices, data logging and telemetry relies upon MQTT software protocol. The system this obtains optimal efficiency on the data channel, which results in lighter cost for GSM/GPRS data transmission.

Value, Service and Maintenance

The machine manufacturer experiences best return on sales revenue, marketing statistics, (i.e. coffee statistics), delivered coffees, and quality type. The machine can be diagnosed in advance, before running out of goods, or well ahead of machine failures and anomalies. Temperature anomalies, pressure and possibly coffee counterfeits can be diagnosed in advance. Maintenance personnel is optimized and ahead of machine anomalies.